Vacuum preloading (consolidation) method was initially proposed by Kjellman at 1952 and was worked out by the Royal Swedish Geotechnical Institute as a method for improving fine grain soil. This method utilises atmosphere pressure as a temporary surcharge for improving fine grain soft soil.

However, in the several following decades, this method was not widely being applied due to the difficulties for maintaining effective vacuum pressure. With the improvement of methodology and technology of producing better vertical drains and airtight sheets, this method was introduced and applied in many countries. Now, this method is widely applied in worldwide, especially in Euro, U.S.A, China, Japan and several other Asian countries.

Vacuum preloading method was introduced into China in 1960’s but was successfully applied until early 1980’s. Since then, this method has been employed in hundreds of projects in China for ground improvement. Furthermore, the development of construction machinery and technique allowed the method been applied in various soil conditions or site conditions.

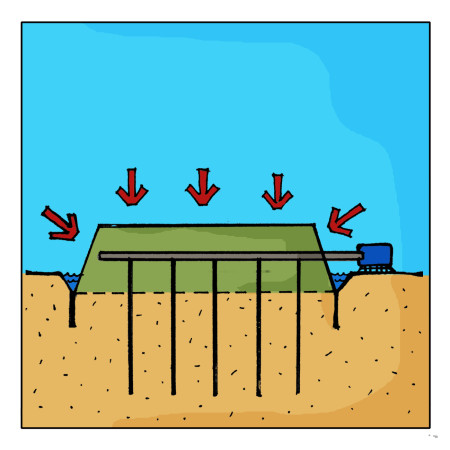

The basic idea of vacuum preloading method is applying a vacuum suction into an isolated soil mass to reduce the atmosphere pressure and pore water pressure in the soil, resulting soil consolidation and effective stress enhance without change the total stress.

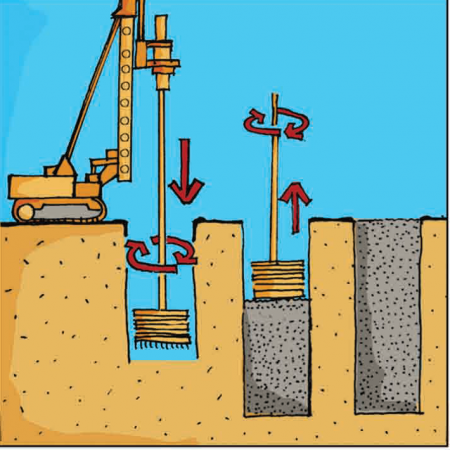

Basically, whole vacuum preloading system consists of drainage system, isolation system and vacuum pumps. Once generated in vacuum pumps, vacuum suction rapidly spreads into soils along drainage system, reducing atmosphere and pore water pressure and forming pressure difference between vertical drains and pore water in soils. This pressure difference cause the pore water flows toward vertical drain which means soil consolidation happens. Vacuum suction keeps taking out water and air and accelerating soil consolidation.

Drainage system is an interconnected network of PVD, horizontal filter pipes and sand layer, forming a complete path for spreading of vacuum suction and water flow.

Isolation system is used to cutoff leakage of water & air below it. It consists of geomembrane, the soft clay itself and cutoff wall if necessary.

In the lateral direction, vacuum suction exerts an inward force into the subsoil which is totally different with surcharge preloading where an outward force is exerted. As a result, in most cases, the sliding failure mechanism could be partly or totally eliminated when applying vacuum preloading method. This is a distinguished advantage when conducting ground improvement on very soft ground or beside existing buildings or infrastructures.

See details here: